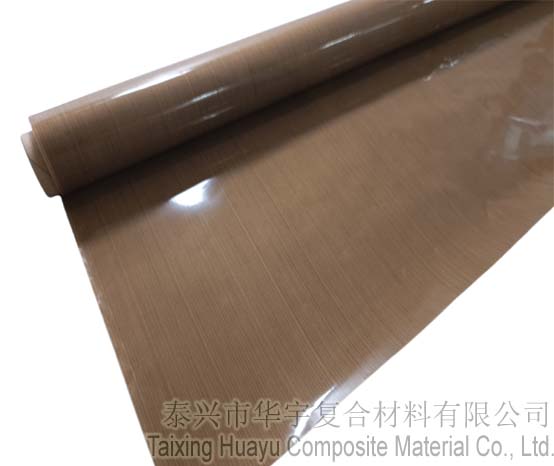

Huayu PTFE-silicone coated fiberglass fabric features a double-sided composite design, with one side coated with PTFE and the other with high-temperature-resistant liquid silicone. Its backing is high-performance electronic-grade fiberglass fabric.

Product Detailed Composition and Features:

1. Base Fabric:

Fiberglass fabric: Provides extremely high mechanical strength and dimensional stability. Fiberglass fabric is inherently heat-resistant (up to 550°C), non-flammable, stretch-resistant, and resilient to deformation, making it an ideal support material for withstanding pressure and high temperatures.

2. Functional Coatings:

PTFE Coating:

Function: Provides excellent anti-stick properties and coefficient of friction.

Features: Chemically resistant, impervious to nearly all chemicals and solvents. Its smooth surface makes residue removal easy.

Silicone Coating:

Function: Provides excellent elasticity, grip, and compression fatigue resistance.

Features: High adhesion (pressure-sensitive) effectively secures the material being processed; transparent or white coating allows for easy viewing of the underlying material; and heat and aging resistance. This structure perfectly combines the advantages of three materials: the strength of glass fiber, the anti-stick properties of PTFE, and the adhesive properties of silicone.

Temperature Range: Depending on the type of silicone, it can typically operate in temperatures ranging from -70°C to +260°C for extended periods, and up to 300°C for short periods.

Main Applications:

1. Hot Cutting/Hot Air Knife Cutting Machines

2. High-Frequency Heat Sealing/Ultrasonic Welding Machines

3. High-Temperature Heat Sealing Machines (e.g., for plastic bag manufacturing)